Products

OUR PRODUCT RANGE

Surface Preparation System

SFS Innovative Solutions Provides Dip Chemical Treatment with PLC Based Transportation or Electrically

operated Over Head Hoist for Material Movement.

Pre-Treatment are designed to improve processing quality and to conserve energy. high-performance washing system (Parallel Separator), and counter-flow circulation tank in the degrease process, and high-pressure spray water washing processes.

Accessories:

- PHE

- Sludge Separator System

- Oil skimmer System

- Auto Dosing System

- Water Treatment System

CED Plant System

- Fully automatic operation, Film thickness can be controlled.

- Uniform coating.

- Better coverage in box and interior surfaces.

- Good coverage of sharp corners.

- No runs and sags.

- No solvent boils.

- Better chip and corrosion resistance.

- Nearly 100% paint utilization.

- Superior in anti-pollution, safety, health hazards.

Liquid Painting System

In Paint shops paint booth is the most important area, the paint application on objects/products is done here, combined with ASU it almost consume half of the power of the overall paint shop. SFS provides booths with advanced energy savings techniques.

- Wet Booths – Circulation of water is provided in these booths to remove excess paints and solvents wet booths are used for mass production.

- Wet booths are of Two types

- Side draft Booth

- Down draft Booth

- Dry Booths – With paint arrestor filters in exhaust these booths are used for touch up/correction work.

There are various Liquid Painting processes meant for different substrates, shape of components based on ultimate Finish and Quality Requirements.

Powder Coating System

Powder Coating is an advanced environment friendly painting method,

which obtains paint film by putting powder paints to an object to be painted

and by melting with the use of Powder Curing Oven. It is the most exciting

finishing method introduced in past 100 years. Powder Coating offers

significant performance advantages with reduced costs. It also meets

environment regulations.(No VOC emission, no paint sludge disposal).

The Powder Coating Plant configuration depends upon sizes and

pes of the articles, coating quality required in conjunction with the color

change intervals. Our specialists in surface coatings have individual answers

and concepts for all these requirements.

Conveyorised powder coating plants are specially designed suitable for

powder coating of high volumes, small & large sizes of components. The

conveyorised applications give better and uniform coating qualities with

better process controls. These plants can be supplied with automated

painting guns and reciprocators etc.

Curving Ovens

Ovens are designed to consume low power/Fuel with a uniform temperature throughout the Oven. Various

safety features like Blower/Heat Source interlock, Pressure release mechanisms and Auto Shut-offs are

provided to make these ovens fully safe. ovens can be heated by:

- Electric Heaters Normally for Small Batch Type Applications.

- Gas Fired- CNG / PNG/ LPG /Propane-Normally used for large ovens . The Gas fired ovens can be

– Direct Fired

– In-Direct Fired. - IR Heated-normally used for Plastic/ABS curing in a Tunnel type Oven.

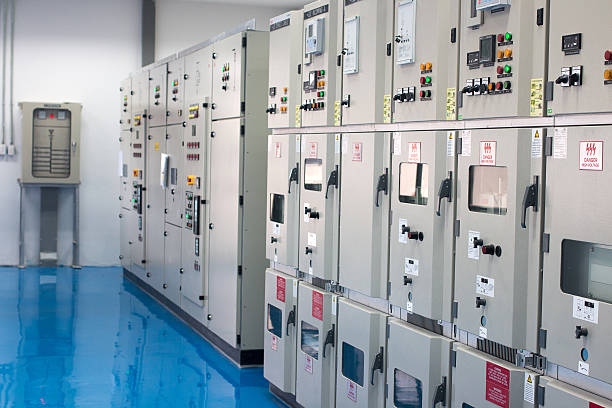

Electric Control Panels

- Conventional type of panels

- PLC/Touchscreen Panels

- Scada Based Control Panels

Shot-Blasting

- Air Operated Shot Blasting Machine -Portable Blasting Machine. – Cabinet Type Shot Blast Machine.

- Airless Shot Blasting Machine – Tumblast Type Shot Blasting Machine. – Table Type Shot Blasting Machine. – Hanger Type Shot Blasting Machine. – Diabola Tunnel Type Shot Blasting Machine. – Belt Conveyor Type Shot Blasting Machine. – Roller Conveyor Type Shot Blasting Machine. – Coil & Wire Shot Blasting Machine. – Shot Peening Machine.

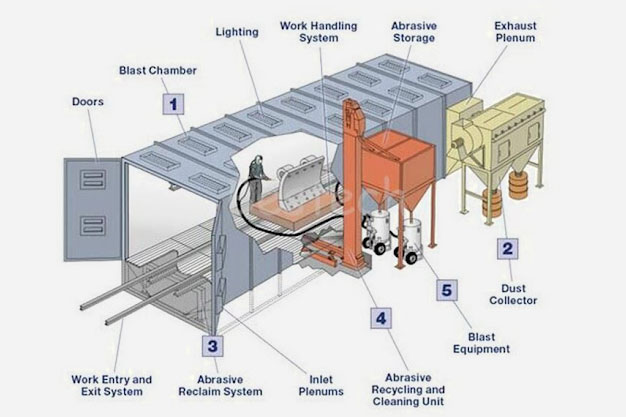

Blast Room Systems

- Abrasive Blasting Machine.

- Abrasive Recovery & Re-cycling System.

- Dust Collectors

- Job Handling System.

- Wall Protection Rubber Lining.

- Illumination.

- Electric Control Panel.

- Operator Safety Wears.

Liquid & Powder Coating Equipment

At SFS, we utilize our technical expertise and experience to deliver turnkey paint finishing systems that ensure highest levels of production efficiency, operating flexibility and superior performance, while offering our customers an unlimited range of coating options.

Our application systems have been enhanced with Intelligent Control system for high volume paint production line and further a remarkable increase in paint shop efficiency.

- Automatic Spray Guns – Conventional / HVLP / Electrostatic.

- High Speed Rotary Atomisers (Bells) / Liquid and Powder.

- Reciprocating systems(Liquid and Powder)

- 1k, 2k and 3k Paint Circulation System

Material Handling System

- I Beam Conveyor.

- Power & Free Conveyors.

- Four Wheel conveyors.

- Closed Track /Clean Room Conveyors.

Types of Conveyors

As the name suggests, this family of conveyors are

installed on or below the floor level. Like overhead

conveyors, the floor conveyors basically comprise of chain,

track, drive unit, take up unit and oiler. Pegs / fixtures /

trolleys / pallets to support the component are generally

required depending on the type of component and

conveyor selected for the said application. The floor

conveyors are generally custom built depending on the

type of component to be handled as well as the

application / process requirement.

The word Overhead implies that these conveyors are installed

overhead, preferably just below the roof height. The conveyor is brought

down at lower levels only for loading / unloading purpose or for any

specific process requirement. An overhead conveyor basically consists of

a track, chain, drive unit, take up unit, oiler and carriers. The track is

supported from roof, floor, wall or columns as per site conditions. The

chain is guided in the track and moved by a drive unit. The take up unit is

provided to adjust the chain tension. The carriers are fixed to the chain at

a predefined pitch. The component to be conveyed is loaded on the

custom designed carrier. The oiler lubricates the chain. SFS has

experience of designing & installing long loops with multiple drive units

duly synchronized. SFS supplied conveyors to cater to unit loads up to

3000kgs.

A hoist is a device used for lifting or lowering a load by means of a

drum or lift-wheel around which rope or chain wraps. It may be manually

operated, electrically or pneumatically driven and may use chain, fiber or

wire rope as its lifting medium. The most familiar form is an elevator, the

car of which is raised and lowered by a hoist mechanism. Most hoists

couple to their loads using a lifting hook.

Transporter

This is the main operational / Production equipment for loading and

unloading jobs into various tanks in the chemical process, with a

programmed cycle. It is effective replacement to traditional hoist with

touch of automation. The cycle is based on timings required in particular

tank, as specified, and also sequenced in such a way that critical tanks

(degrease, de-rust, zinc phosphate and WDO) are treated on priority, so

jobs will be removed from these tanks with minimal time loss (to avoid

damage to job).

To achieve this there an overhead motorized wagon, mounted on wheels

which can travel across all tanks & load / unload stands. Further this

wagon has an up / down arrangement, also motorized, for lifting &

lowering jobs into tanks. The machine also has flight bar which can carry

the loaded basket.

Air Supply System

An air handling unit(AHU) is the composition of elements mounted in large, accessible box-shaped units called modules, which house the appropriate ventilation requirements for purifying, air-conditioning or renewing the indoor air in a building or premises.

They are usually installed on the roof of buildings and, through ducts, the air is circulated to reach each of the rooms in the building in question.

Main functions of an AHU

In addition to managing the proper ventilation of the interior with outside air, the AHU performs other functions:

- Filtration and control of the quality of the air that will reach the interior, thanks to the air purification filters, and depending on the retention of these filters, the air will be clean.

- Control of the air temperature that regulates the air conditioning system in cold or hot, so that the thermal sensation in the interior is the desired one.

- Relative humidity monitoring for greater indoor comfort.

For its part, the places for which the AHU is intended are those in which the flow of people is very large and accumulates many people at the same time and whose natural ventilation is limited: hotel dining rooms, function rooms, restaurants, convention halls… It is also a suitable option for those spaces with very high hygiene requirements: laboratories, clean rooms or operating theatres, among others. An AHU can also be used to ventilate places where air conditioning is provided by radiators or underfloor heating, for example.

What does an AHU consist of?

- Air intake: air handling units collect air from outside, which is treated and distributed throughout the rooms; and/or indoor air that is “recycled”.

- Filter: depending on the air purity requirements, the filter applied will have a higher or lower particle, viruses, bacteria, odours, and other air pollutants retention.

- Fan: this is an electromechanical system that powers the air to expel it from the AHU to the ducts that distribute the air throughout the rooms.

- Heat exchangers: devices that transfer temperature between two fluids, in this case, coolant and air, separated by a solid barrier.

- Cooling coil: the air passing through this module is cooled. In this process, water droplets can be generated, which are collected in a condensate tray thanks to the built-in droplet separator.

- Silencer: coatings that considerably reduce the sound level of the installation.

- Plenums: empty spaces in which the air flow is homogenised.

Shower tester booth

Cleanroom Enclosure Systems

Cleanroom enclosures built to the highest quality standard for todays critical environments. Modular cleanroom enclosures for every industry application. We supply all of the parts, labor and engineering needed to construct critical environment enclosure systems. Our services include initial design concept and on-site installation.

Modular cleanrooms are affordable, pre-fabricated enclosures. These cleanrooms offer a quality finish, professional look and can be custom built to meet the needs of the application. Modular cleanrooms can be integrated into current architecture and mechanical systems and generally do not disrupt current operations during installation.

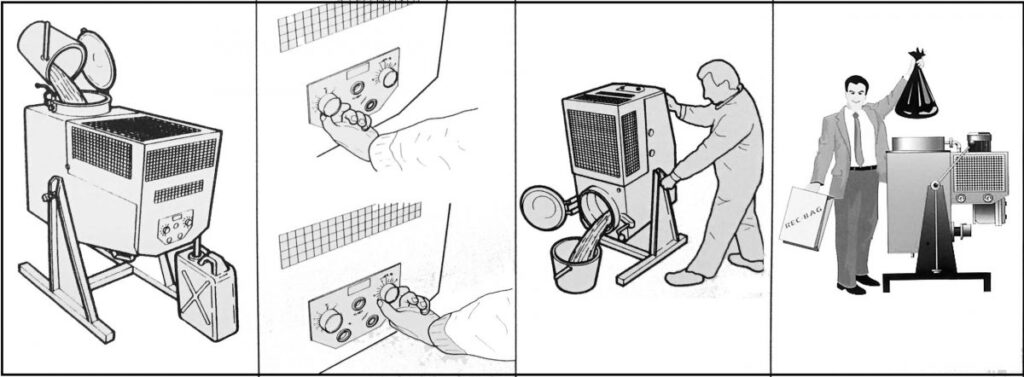

Solvent Recovery System

Distillation units which allow the purification and reuse of polluted solvents used for washing, degreasing, etc. Ex-Explosion-Proof Electric Construction (ATEX) for the treatment of flammable and non-flammable solvents.

Solvent recovery machines are industrial distillation units designed to purify and recycle used thinner, solvents, and cleaning agents, allowing them to be reused in processes like paint, ink, and coating manufacturing. These systems are highly efficient, often achieving a recovery rate of up to 99%, which significantly reduces waste disposal costs and solvent purchasing expenses.

Key Features of Thinner Recovery Machines:

- Distillation Technology: They use a peripheral heating jacket filled with diathermic oil, heated by electrical elements, to distill solvents and separate them from contaminants like resins, pigments, and polymers.

- Safety and Standards: units such as the DISTATIC series are explosion-proof, featuring ATEX approval for safe treatment of flammable solvents.

- Model Options (Standard Series):

- DI 15 / DI 30 / DI 60 / DI 120 / DI 160: Ranging from 15 to 160 liters of useful loading capacity, with distillation times typically between 3 and 5 hours.

- DIQ Series: Features a scraper inside the boiler for managing thicker, more viscous contaminants.

- “Rec-Bag” System: Utilizes special bags that hold the residue, allowing for easy, clean, and safe removal of solid contaminants without cleaning the boiler.

- Automation: They offer automatic operation, including automatic loading, vacuum options for low-temperature distillation of high-boiling solvents, and automatic residue discharge.

Common Applications:

- Printing & Packaging: Cleaning flexographic photopolymer plates.

- Automotive: Cleaning paint spray guns.

- Manufacturing: Cleaning agents for electronics (trichloroethylene), optics (IPA/ethanol), and furniture production.

Typical Specifications (60L Unit):

- Capacity: 60 liters per batch (103L total boiler volume).

- Temperature Range: 50 – 180 °C.

- Cooling: Stainless steel condenser, typically air-cooled.

These units are designed to minimize environmental impact and provide a fast return on investment for businesses utilizing large volumes of cleaning solvents.

Recycling machines and treatment systems are used in a variety of applications, including:

- Furniture manufacturing: solvent distillation units are commonly used by furniture manufacturers to purify and reuse solvents used for cleaning paint systems.

- Printing and flexography: used in the printing and flexography industry to treat and recycle water and solvents.

- Surface treatment: used in the metal degreasing process, helping customers reduce waste and improve environmental performance.

- Fiberglass manufacturing: used in the fiberglass manufacturing industry to treat and recycle solvents and water.

- Paints and inks production: used in the production of paints and inks to reduce waste and improve environmental performance.